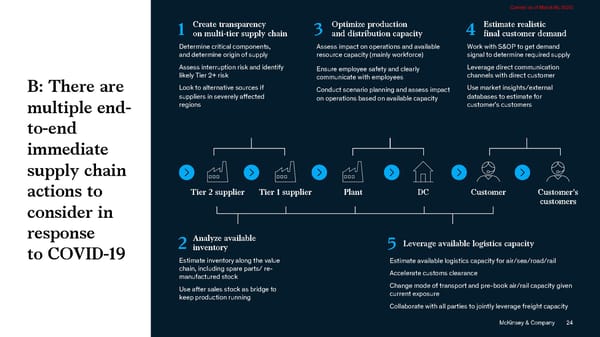

Current as of March 16, 2020 1 Create transparency 3 Optimize production 4 Estimate realistic on multi-tier supply chain and distribution capacity final customer demand Determine critical components, Assess impact on operations and available Work with S&OP to get demand and determine origin of supply resource capacity (mainly workforce) signal to determine required supply Assess interruption risk and identify Ensure employee safety and clearly Leverage direct communication likely Tier 2+ risk communicate with employees channels with direct customer B: There are Look to alternative sources if Conduct scenario planning and assess impact Use market insights/external suppliers in severely affected on operations based on available capacity databases to estimate for multiple end- regions customer’s customers to-end immediate supply chain actions to Tier 2 supplier Tier 1 supplier Plant DC Customer Customer's consider in customers response Analyze available to COVID-19 2 inventory 5 Leverage available logistics capacity Estimate inventory along the value Estimate available logistics capacity for air/sea/road/rail chain, including spare parts/ re- Accelerate customs clearance manufactured stock Use after sales stock as bridge to Change mode of transport and pre-book air/rail capacity given keep production running current exposure Collaborate with all parties to jointly leverage freight capacity McKinsey & Company 24

COVID-19 Facts and Insight Page 23 Page 25

COVID-19 Facts and Insight Page 23 Page 25