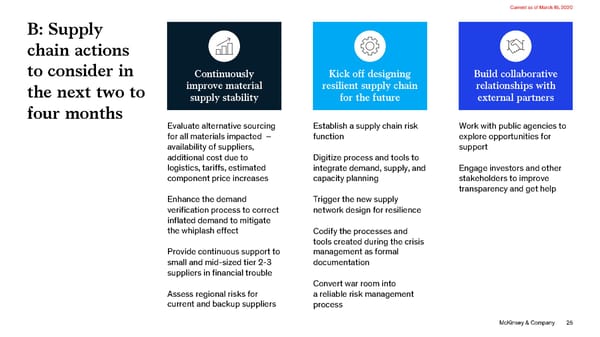

Current as of March 16, 2020 B: Supply chain actions to consider in Continuously Kick off designing Build collaborative the next two to improve material resilient supply chain relationships with four months supply stability for the future external partners Evaluate alternative sourcing Establish a supply chain risk Work with public agencies to for all materials impacted – function explore opportunities for availability of suppliers, support additional cost due to Digitize process and tools to logistics, tariffs, estimated integrate demand, supply, and Engage investors and other component price increases capacity planning stakeholders to improve transparency and get help Enhance the demand Trigger the new supply verification process to correct network design for resilience inflated demand to mitigate the whiplash effect Codify the processes and tools created during the crisis Provide continuous support to management as formal small and mid-sized tier 2-3 documentation suppliers in financial trouble Convert war room into Assess regional risks for a reliable risk management current and backup suppliers process McKinsey & Company 25

COVID-19 Facts and Insight Page 24 Page 26

COVID-19 Facts and Insight Page 24 Page 26